“We were impressed that ABB reached out to us to let us know of a potential problem,” says Andrew Agosto, Vice President of Sports Architecture. This meant that all 21 of the drives could fail prematurely. Six months after Uni-Systems Engineering purchased 21 ABB ACS880 drives for the project, ABB informed them that some of the drives had failed lifecycle testing due to a component issue. This was an important benefit with the ACS880-11 drives since they had just been introduced to the market when they were selected for the Globe Life Field project. As cabinet/bogie assemblies were completed, they shipped from Minnesota to Texas to be hoisted on the roof.ĪBB continuously tests products, even after release, to ensure that performance, safety and lifetime expectancy are achieved. This allowed the team to develop the needed program and find the right configuration for quick and accurate drive setup. To make this as simple as possible, ABB provided an ACS880 demo case to Uni-Systems Engineering. However, each drive had to be programmed for the application. To ensure uptime and flexibility, redundancy is built-in to the design (although the duty cycle is low as some stadiums seldom open), so the roof can move even with up to four drives inoperable.

/cloudfront-us-east-1.images.arcpublishing.com/gray/G6KZNN7IUVLLPNXUTKTW2HRJYE.jpg)

Uni-System Engineering’s shop in Minnesota was responsible for assembling ten cabinets, each with two drives, and then mounting the cabinets to the bogies. The schedule was the next biggest challenge in this build. Alex Krueger, Electrical Engineering Manager, explains that they have continued to use ABB drives because “Not only have the drives performed well in other installations, ABB is a good supplier – they provide local sales support and troubleshooting, as well as educational opportunities relevant to what we do daily.” For this project, Uni-Systems utilized the ACS880-11, the latest technology in the ABB regenerative drive family. Uni-Systems Engineering has been using ABB ACS800 drives since the mid-2000s when they first installed them in the Cardinals football stadium. Six wheels on each of the powered bogies are driven by a 10 HP motor, and each powered bogie is controlled by two 40HP ACS880 regenerative drives, with each drive powering three motors, for a total of 20 ABB drives on the system.ĪBB ACS880 regenerative drives were chosen to eliminate the need for 3 rd party regen units to generate energy. Each bogey rides on six wheels, with five of the bogies on each rail powered.

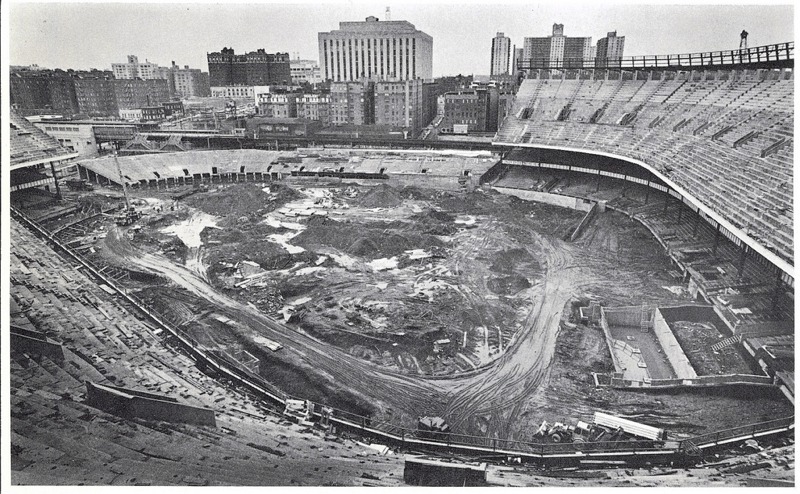

The sheer size was impressive, weighing 24 million pounds and utilizing two sets of parallel rails with 10 bogies (train cars) per rail.

#Globe life field install#

Globe Life Field is the largest single panel retractable roof in the world.įor Uni-Systems Engineering, the company selected to design and install the roof mechanization, the Globe Life Field retractable roof was the largest they had built to date. In this single panel design the entire roof panel can be removed from the stadium and “parked” over the plaza area.

A single panel design was chosen, which is easier to control and position than multi-panel designs that utilize an accordion system.

0 kommentar(er)

0 kommentar(er)